- Homepage

- News and Features

- How to reduce breakdowns and get the best from your machinery

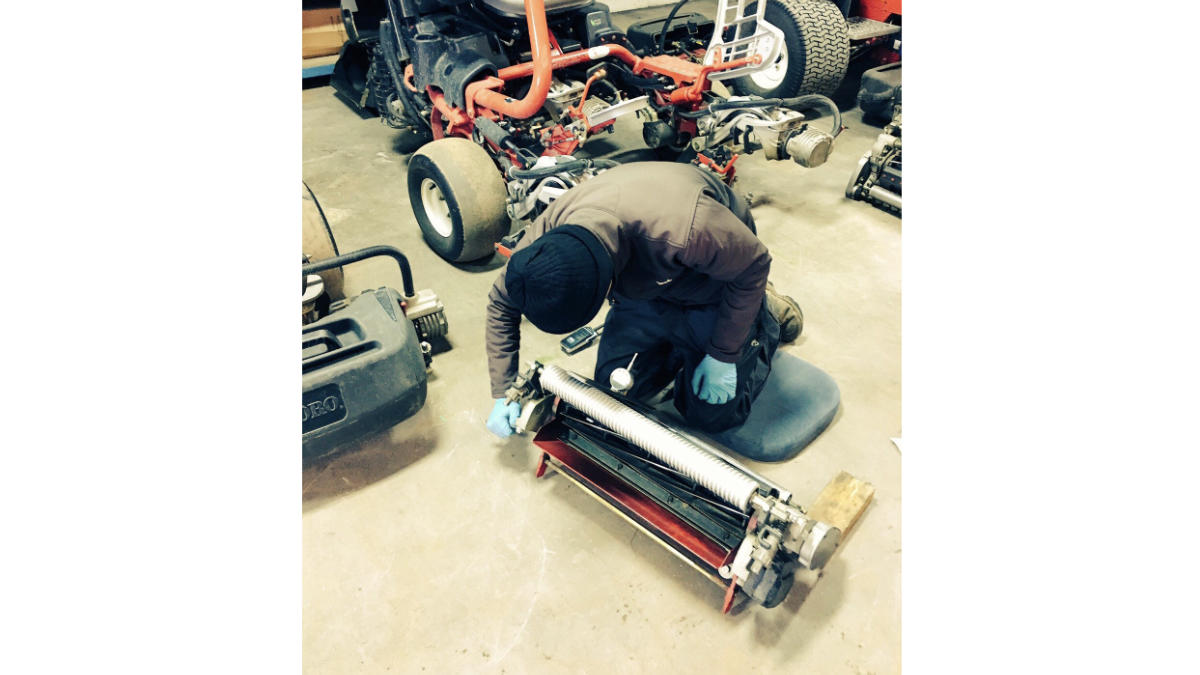

How to reduce breakdowns and get the best from your machinery

Over the next few months, across several related articles, we will explore how to improve our knowledge of maintaining and repairing turfcare machinery.

We’ll be starting the articles this month by reviewing the first step in any workshop repair process, namely preventative maintenance. Then throughout the series we will look at articles covering electrics, hydraulics, engines, cutting units, chemical application machinery and national sprayer testing requirements. Any turfcare maintenance programme always starts with good day‐to‐day management or, to put it another way:

Maintenance 101

Pre‐start checks

The first step to avoiding costly repairs is to understand the importance of operators doing their pre‐start checks. For anyone using work equipment there are strict regulations in place: the provision and use of work equipment regulations (PUWER). PUWER is clear in two areas in particular:

1. ‘It is used only by people who have received adequate training’

‘Adequate training’ is open for interpretation and will vary from person to person. One way to meet requirements is to use a professional trainer, backed by

an awarding body, to cover this essential training. The current minimum machinery standards for pre‐start checks for greenkeeping apprenticeships are: appentices must carry out preparation (oil and fuel) of the equipment for the task.

My question to you is always ‘are these minimum standards satisfactory to keep the machinery in the best possible condition and so prevent the need for costly repairs?’

2. ‘It is safe for use, maintained in a safe condition and, in certain circumstances, inspected to ensure this remains the case’

‘Safe for use’ and ‘maintained in a safe condition’ are important here. If we are failing to do the correct pre‐start checks, do we feel this is satisfactory to maintain the machine in a safe condition for use?

Additionally, are basic checks ensuring we are complying with PUWER where we need to inspect to ensure the machinery remains safe to use? The importance of complying with PUWER and carrying out pre‐start checks is to maintain safety standards. This will, in turn, keep the machinery in the best possible condition, preventing the need for costly repairs and so it forms the first step in maintaining our machinery.

Routine service schedule

Having the correct pre‐start checks in place is one step and helps identify potential issues before they become a costly repair. Likewise, routine servicing will help prevent breakdowns and the need to spend money on repairs.

PUWER legislates that machinery must be ‘safe for use, maintained in a safe condition and inspected to ensure this remains the case’. It also states that anyone maintaining work equipment must have had adequate training.

There are a number of options available to greenkeepers and technicians to both develop and maintain their skill levels. Some manufacturers run courses specific to their brand and there are also specific nationally‐accredited turfcare machinery maintenance courses available. Whatever route you decide is right for you, the current training being offered is delivered around your work schedule and can be delivered away from work, online or at your place of work.

Routine service work is about planning and most operator manuals will inform you of the recommended service intervals. There are plenty of inexpensive management systems available to help you with this planning. You could build a basic spreadsheet to help you keep track of service dates, parts numbers and costs.

Obtaining the service manual for each piece of equipment will be a significant help. Although not all manufacturers provide service manuals, they are becoming more available and downloadable online.

Machinery breakdown issues

We work in particularly harsh environments and are out in all weathers and temperatures, while the build‐up of grass and debris or washing machinery down can all have a detrimental effect on the machinery we use. After correct servicing, backed up by the proper pre‐start checks, it is still inevitable that at some point in our machinery’s life span that it will fail. When these failures happen, we have one of two decisions: call out the nearest turfcare specialist technician or, if we have had adequate training, we can start the fault‐finding process ourselves.

This series of articles is aimed at those who want to develop the skills to be able to take the first steps towards identifying issues. If we then have the ability to fix this issue, we can do so without the need to call out a technician. If, after identifying the problem, we acknowledge that it is beyond our skill set, we will understand that it requires a turfcare specialist technician to be called out.

Where to look next...

John Deere | Just Click & Collect

![News_Parts Click & Collect[3].jpg](https://www.bigga.org.uk/static/7421b020-4013-4a76-92330083f522e5ea/1200x675_highestperformance_/NewsParts-Click-Collect3.jpg)

Ordering parts online has got a whole lot easier with the new John Deere Parts Click & Collect service.

Just visit partscatalog. deere.com, enter your machine’s model/name or serial number and browse all available parts. Then select and reserve them with one click and collect them at your dealer in a single visit... it really is that simple.

During the ongoing COVID‐19 pandemic, the ability to order parts via the internet has never been more relevant. The updated John Deere Parts website is the new way for customers to find information about the parts you need, add them to a shopping cart and order them from your local dealership.

Visitors to the main www.deere.co.uk website can also easily access John Deere Parts from the Parts & Service tab at the top of the home page, by clicking on ‘Parts’ at the top of the drop‐down menu, when the ‘Search by’ panel is then visible.

To get availability and price details in the online parts catalogue, you just need to select a dealer by entering your postcode; customer name and address details are only required once you proceed to the shopping cart to confirm and check out the order.

Anyone who has already registered to use the MyJohnDeere.com website to access JDLink telematics information from their machines will also find links to several apps on that site’s homepage, including one called ‘Find Parts’, so your details will be used automatically in John Deere Parts to save time.

John Deere Parts is designed to work across various platforms, including PC, laptop, tablet and smartphone, which is a major improvement over the old JDParts site. Features include:

/ search by model, PIN or part number;

/ graphical navigation;

/ display of price and availability based on dealer settings;

/ shopping list creation, email to selected dealer and print;

/ preferred dealer selection and checkout.

Eighty per cent of the parts you need can usually be filled directly from the local dealer, who can also see the stock available at other dealerships. John Deere’s worldwide parts network provides instant information on parts availability, day or night, with orders normally shipped from anywhere in the world within 24 hours, and overnight or even same day delivery on the UK mainland.

The company has recently invested almost US$1m in the parts warehouse at John Deere Limited’s UK & Ireland headquarters. This has included the provision of new barcode scanning equipment plus four new low‐level order pickers, to streamline the Langar‐based parts operation.

Alongside this investment, a further US$19.8m has been spent on expanding the company’s European Parts Distribution Centre in Germany, which stocks over 300,000 different parts. This facility’s advanced logistics and packaging systems can ship a next‐day delivery order in just two hours after it comes in.

For further details of the range of parts available for John Deere golf and sports turf equipment, visit www.deere.co.uk/en/ parts‐and‐service/parts/ golf‐and‐sports‐turf‐parts

Author